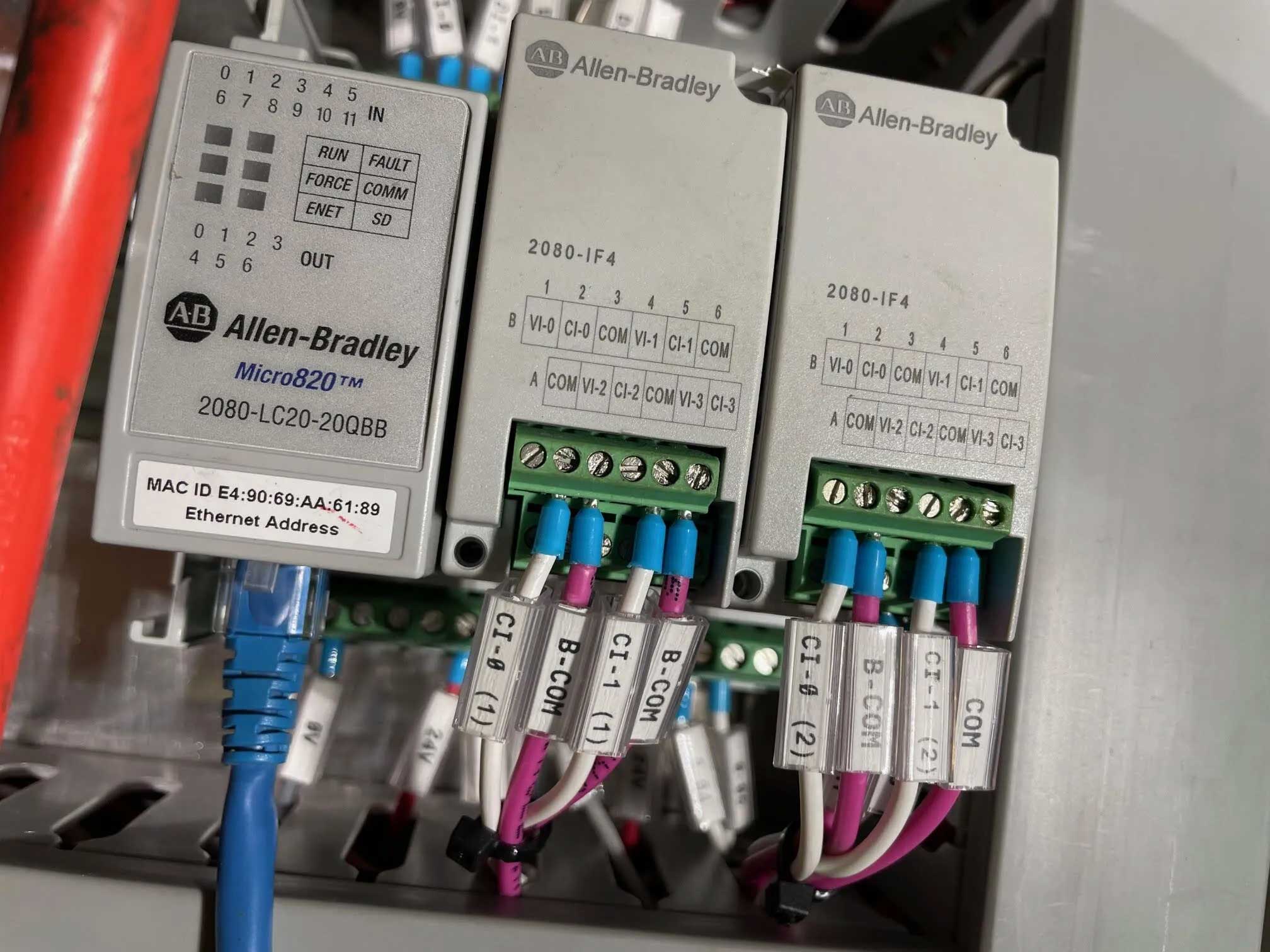

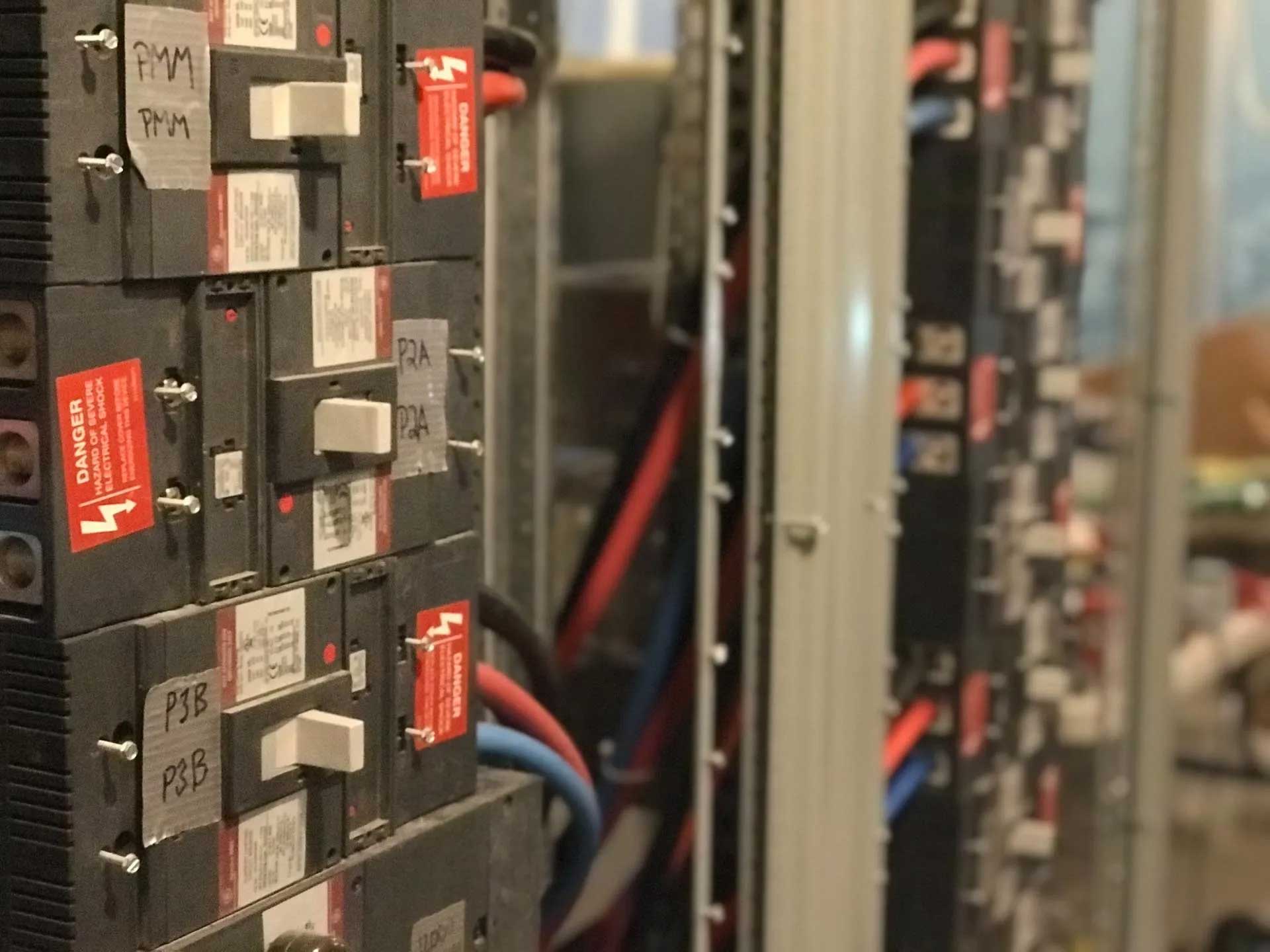

Programmable Logic Controllers (PLCs) are the cornerstone of industrial automation applications, and they rely on specific programming languages to control and manage various processes within manufacturing environments. Several programming languages are commonly used in PLCs to suit different application requirements.

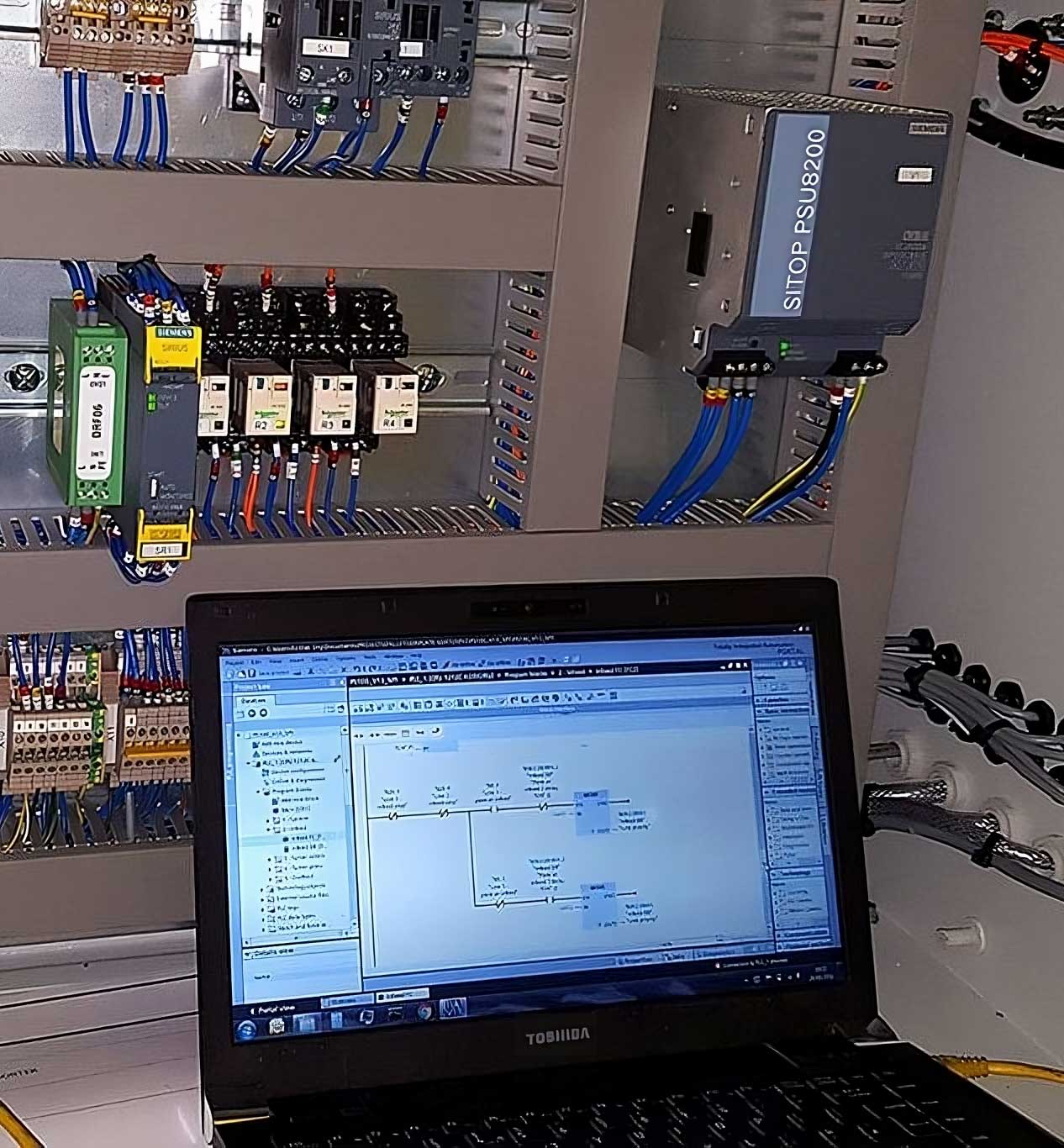

- Ladder Logic (LAD) - Ladder Logic is the most traditional and widely used PLC programming language. It's graphical and mimics electrical relay logic, making it intuitive for engineers and electricians to understand and troubleshoot.

- Function Block Diagram (FBD) - FBD is another graphical language that represents functions and their interconnections. It's well-suited for complex applications that require modularity and reusability.

- Structured Text (ST) - ST resembles high-level programming languages like C or Pascal. It's ideal for complex mathematical calculations and algorithm-based control applications, offering more flexibility in coding.

- Instruction List (IL) - IL is a textual, low-level language often used for simple, time-critical tasks and for those familiar with assembly programming.

- Sequential Function Chart (SFC) - SFC is a graphical language used for managing complex sequences of operation, particularly in batch processes.

Our PLC programmer chooses the most suitable language based on the specific automation application's requirements, ease of maintenance, and the expertise of the engineering team. These languages, along with their adaptability, ensure that industrial automation systems efficiently and reliably manage and control processes in diverse manufacturing settings.